Moespeeds

Well-Known Member

Improper transmission shim can cause a host of problems, from vibration, leaking seals and primarys, to broken motor plates, jackshafts, and mainshafts. So many guys, shops included, ignore this simple procedure when they remove their transmission. I just shimmed my Redneck last night, so I took a few pictures and here's a quick how-to.

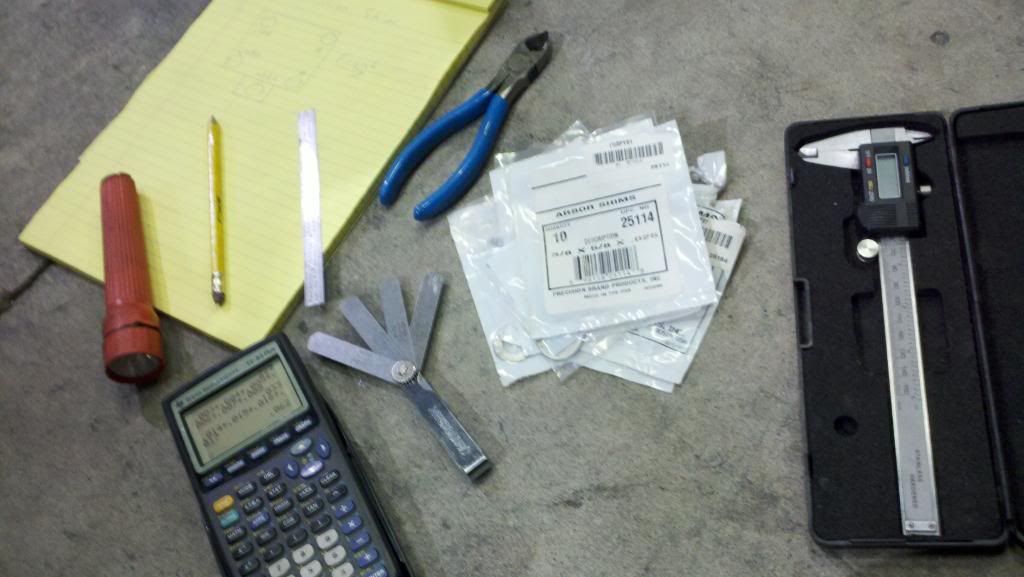

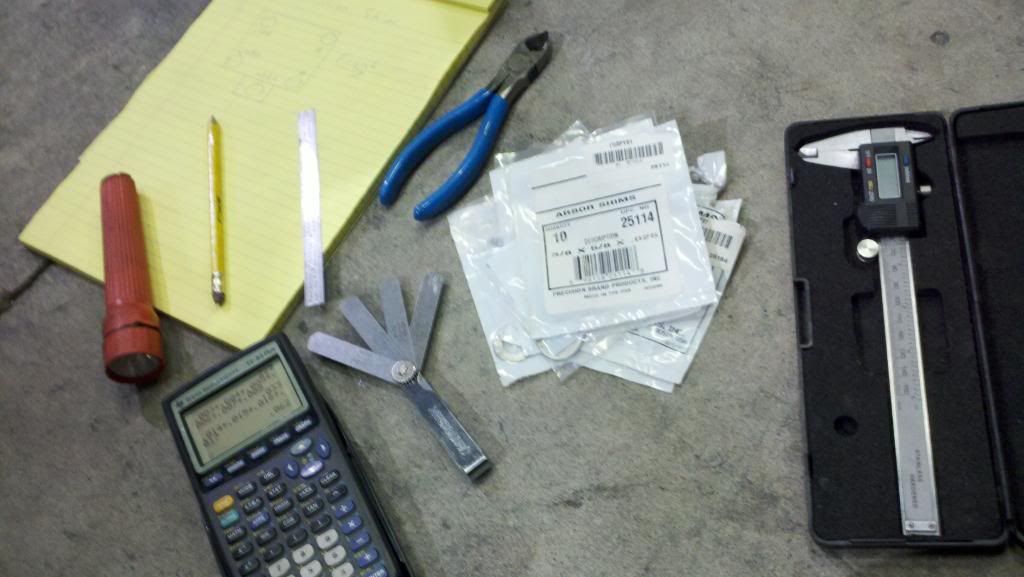

First we need to gather our tools. You'll need a feeler gauge, available at any parts store, needle nose pliers, and a flashlight. It also helps to have a caliper so you can verify your shims, and a notebook to write everything down. I use Arbor Shims from Grainger, and always keep them around. For my Revtech transmission I use 3/8" ID shims but for your Big Dogs I you'll need 7/16" ID. Check your transmission mounting bolts, the ID of the shim needs to match. I buy 1 pack each of .025, .010, and .005. Anything smaller than .005 is like using tinfoil.

First completely remove the belt, starter, primary, and motor plate. Your motor plate is the back side of your primary that actually bolts to the engine and transmission. Loosen your transmission mounting bolts, back them off at least 1/16". Make sure the trans is completely free to move. On my bike it's easy, on later model Big Dog's it's a pain in the ass, but a double offset wrench helps bigtime. Some guys loosen the motor mounting bolts, but there is really no need, just check them over. Clean all mating surfaces and remove any burrs or irregularities with a file. I use brake cleaner and a scotchbrite pad. It's important to get any dirt or crud that might be between the motor plate and transmission or engine.

Now what we are trying to accomplish is to get perfect horizontal and vertical alignment between the mainshaft on the motor, and the mainshaft on the transmission, as well as relieve any deflection or stress on the motor plate. The motor plate is a beefy member, so we will use it as our alignment guide. Slide the motor plate back on, up against the engine, but leave the transmission loose and backed off. Install and hand tighten just the motor plate to engine bolts. You don't have to torque them, but make them tight so there is no space, and verify that you have a good tight fit to the engine. Now, slide the transmission up to the motor plate, and hand tighten those bolts, again verifying that you have a good, tight fit. Now torque all the motor plate bolts to spec, 18ft lbs for 5/16-18 bolts, in a criss cross pattern. It doesn't matter where you start, but make sure you go in a criss cross pattern, engine and transmission.

Now go around to the right side of the bike with your flashlight and feeler gauge. It's tough to see under there, but you're looking at where the transmission sits on the frame's transmission mounting plate. Your BD has 4 mounting points, my bike has 5.

Now take out your feeler gauge, and slide it under each mounting point, checking for space. The smallest gauge you should bother with is .005, anything less isn't really worth the trouble. A human hair is .002-.007. Stack mutliple "feelers" until you can just slide them under each point with some resistance, then round down to the nearest .005.

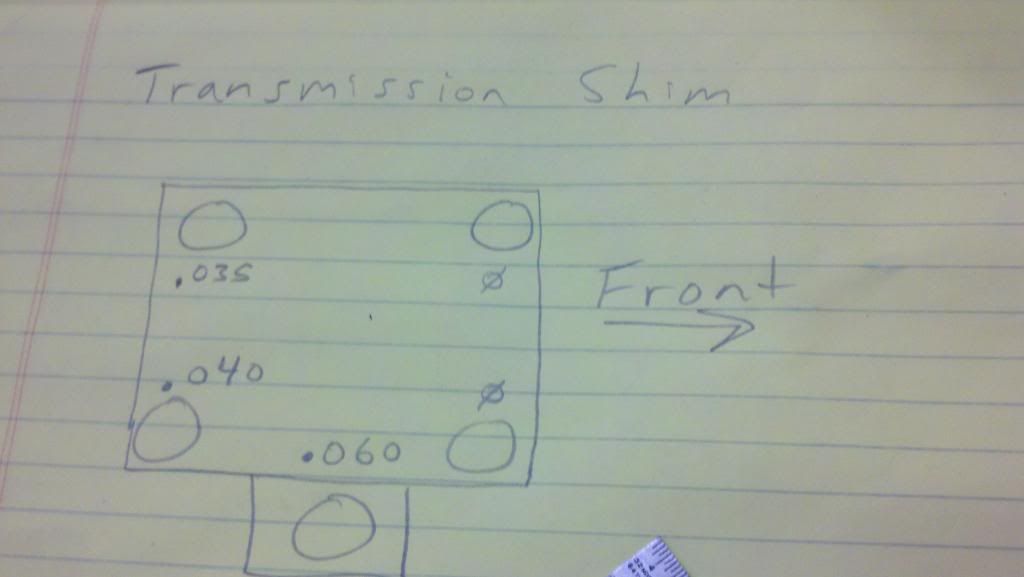

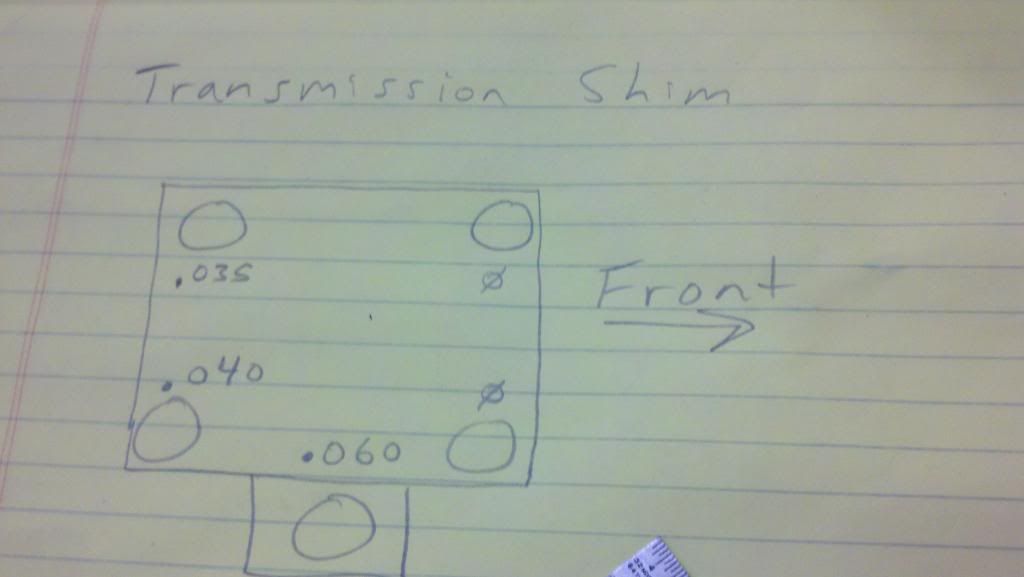

Draw yourself a diagram, and record the shim needed at each mounting point.

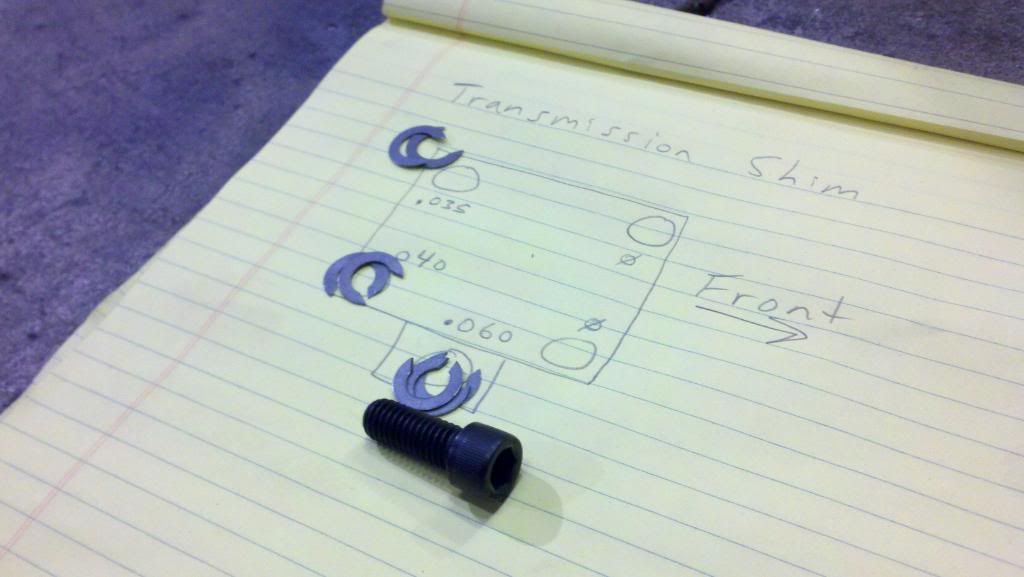

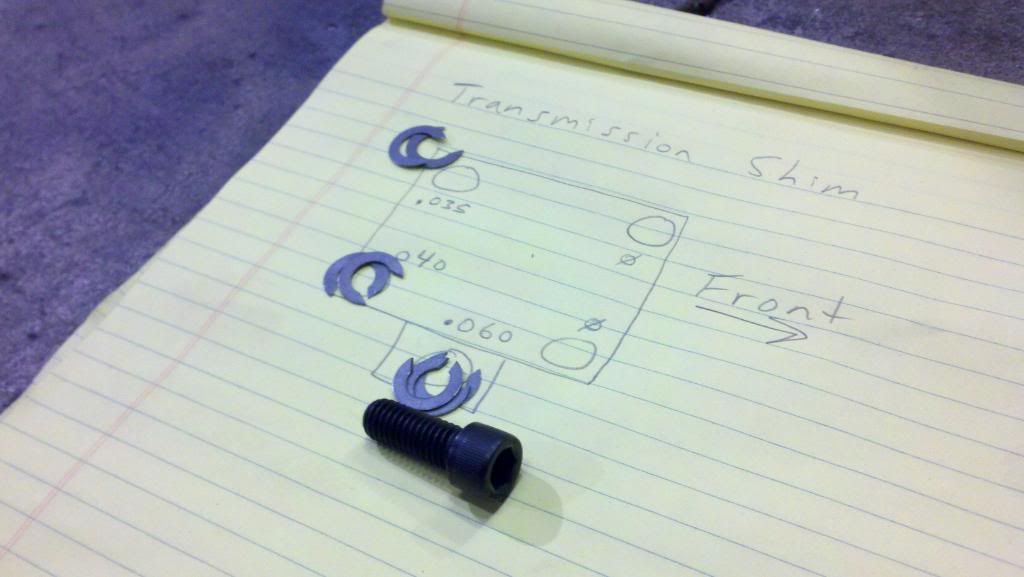

Now there are two ways to install your shims. On Big Dogs with the larger mounting bolts and shims, I typicall just cut the shims into "C" shapes with wire cutters. This way I can slide them under the transmission without taking it out. Be careful, they are fucking sharp, wear safety glasses while cutting them. Make sure you don't leave any raised burrs that might affect your thickness.

The second method that I use in this case is to remove the transmission completely, and just put the shims on the bottom like washers. This works well on smaller mounting bolts, like on my bike. I use grease to hold them in place while I re-install the transmission.

Either way, lay all your shims out on your diagram, and double check the thickness with a caliper. If you cut them, make sure they will slide over a test bolt the same size as those on your tranmission.

If you cut your shims, put the thickest one towards the bottom and slide them under each mounting point, using a screwdriver, credit card, or whatever to shove them in tight. Once you have all your shims installed, double check for any space at each mount and try to rock the transmission. Make sure there is no play.

The last step is to torque your transmission mounting bolts. You should now have perfect engine to transmission alignment. A quick test is to remove the motor plate. It should now slide on and off easily, no need for a mallet to tap it loose. Now put your shit back together and go ride!

First we need to gather our tools. You'll need a feeler gauge, available at any parts store, needle nose pliers, and a flashlight. It also helps to have a caliper so you can verify your shims, and a notebook to write everything down. I use Arbor Shims from Grainger, and always keep them around. For my Revtech transmission I use 3/8" ID shims but for your Big Dogs I you'll need 7/16" ID. Check your transmission mounting bolts, the ID of the shim needs to match. I buy 1 pack each of .025, .010, and .005. Anything smaller than .005 is like using tinfoil.

First completely remove the belt, starter, primary, and motor plate. Your motor plate is the back side of your primary that actually bolts to the engine and transmission. Loosen your transmission mounting bolts, back them off at least 1/16". Make sure the trans is completely free to move. On my bike it's easy, on later model Big Dog's it's a pain in the ass, but a double offset wrench helps bigtime. Some guys loosen the motor mounting bolts, but there is really no need, just check them over. Clean all mating surfaces and remove any burrs or irregularities with a file. I use brake cleaner and a scotchbrite pad. It's important to get any dirt or crud that might be between the motor plate and transmission or engine.

Now what we are trying to accomplish is to get perfect horizontal and vertical alignment between the mainshaft on the motor, and the mainshaft on the transmission, as well as relieve any deflection or stress on the motor plate. The motor plate is a beefy member, so we will use it as our alignment guide. Slide the motor plate back on, up against the engine, but leave the transmission loose and backed off. Install and hand tighten just the motor plate to engine bolts. You don't have to torque them, but make them tight so there is no space, and verify that you have a good tight fit to the engine. Now, slide the transmission up to the motor plate, and hand tighten those bolts, again verifying that you have a good, tight fit. Now torque all the motor plate bolts to spec, 18ft lbs for 5/16-18 bolts, in a criss cross pattern. It doesn't matter where you start, but make sure you go in a criss cross pattern, engine and transmission.

Now go around to the right side of the bike with your flashlight and feeler gauge. It's tough to see under there, but you're looking at where the transmission sits on the frame's transmission mounting plate. Your BD has 4 mounting points, my bike has 5.

Now take out your feeler gauge, and slide it under each mounting point, checking for space. The smallest gauge you should bother with is .005, anything less isn't really worth the trouble. A human hair is .002-.007. Stack mutliple "feelers" until you can just slide them under each point with some resistance, then round down to the nearest .005.

Draw yourself a diagram, and record the shim needed at each mounting point.

Now there are two ways to install your shims. On Big Dogs with the larger mounting bolts and shims, I typicall just cut the shims into "C" shapes with wire cutters. This way I can slide them under the transmission without taking it out. Be careful, they are fucking sharp, wear safety glasses while cutting them. Make sure you don't leave any raised burrs that might affect your thickness.

The second method that I use in this case is to remove the transmission completely, and just put the shims on the bottom like washers. This works well on smaller mounting bolts, like on my bike. I use grease to hold them in place while I re-install the transmission.

Either way, lay all your shims out on your diagram, and double check the thickness with a caliper. If you cut them, make sure they will slide over a test bolt the same size as those on your tranmission.

If you cut your shims, put the thickest one towards the bottom and slide them under each mounting point, using a screwdriver, credit card, or whatever to shove them in tight. Once you have all your shims installed, double check for any space at each mount and try to rock the transmission. Make sure there is no play.

The last step is to torque your transmission mounting bolts. You should now have perfect engine to transmission alignment. A quick test is to remove the motor plate. It should now slide on and off easily, no need for a mallet to tap it loose. Now put your shit back together and go ride!

Last edited: