cj-in-kc

Member

My process of alignment / adjustment of the rear tire, simply measure the distance between dead center on the head of the axel bolt to the apex point on the rear of the swing-arm (as shown in illustration 2b below  lol) or use the handy tool as shown below.

lol) or use the handy tool as shown below.

Left Drive Illustration 2B

Axel Bolt ---- distance ---- Apex of frame/swingarm

@ --------------------------- >

|------------- x inches --------|

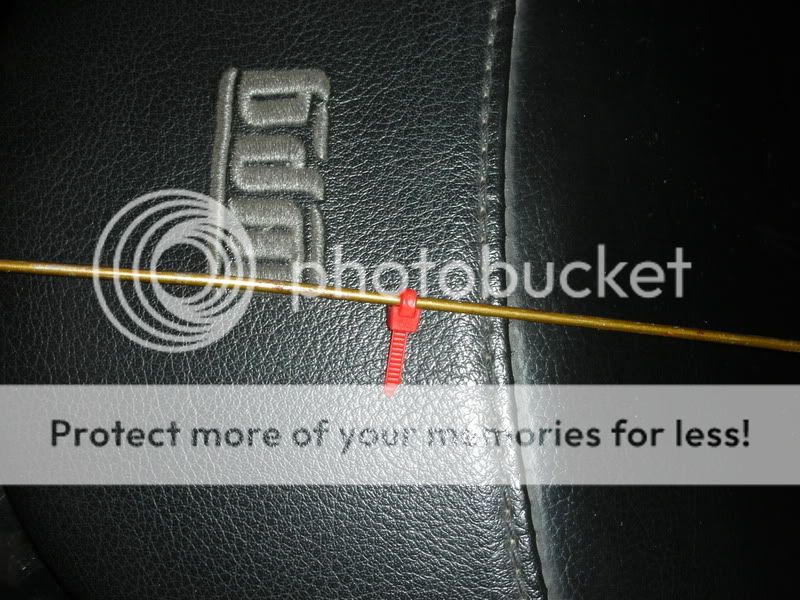

Allen wrench that fits in the screw hole left when removing the cover. Use a o-ring (or in this case piece of plastic) to "mark" the distance on one side, after getting the belt close to the correct tension.

Now do the same on the other side. As you can see in the picture below, the axel needs to get moved to the rear, when compared to the distance marked on the other side of the bike. Go ahead and loosen or tighten the screw that moves the axel forward / backward until the distance is the same on both sides.

Once complete, double check tension...

Chuck

lol) or use the handy tool as shown below.

lol) or use the handy tool as shown below.Left Drive Illustration 2B

Axel Bolt ---- distance ---- Apex of frame/swingarm

@ --------------------------- >

|------------- x inches --------|

Allen wrench that fits in the screw hole left when removing the cover. Use a o-ring (or in this case piece of plastic) to "mark" the distance on one side, after getting the belt close to the correct tension.

Now do the same on the other side. As you can see in the picture below, the axel needs to get moved to the rear, when compared to the distance marked on the other side of the bike. Go ahead and loosen or tighten the screw that moves the axel forward / backward until the distance is the same on both sides.

Once complete, double check tension...

Chuck

Last edited: