Axel

Active Member

Hi,

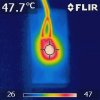

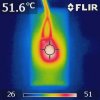

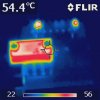

Just an update: I got a return of an EHC where the customer had a short circuit at the horn output cable in the harness. The box had smoked and there was a hole inside. The internal self resettable fuses ( 2 x 9 Ampere parallel in the main line ) had not trip what followed in a burned copper track. I have checked the data sheet of the fuses and have seen that the trip time is far too much. I called to the distributor here and they also told me that the trip time measurements were made in the air and not in potting compound. A potting compound will increase the trip time due to the heatsink function of the potting material. So, I´ll try to change the main fuse to a 7 Ampere device what can also drive the starter solenoid ( 18 Ampere ) for about 20 seconds at 20 degree until it will switch off ( look at page 14, diagram K, RUEF700 of the pdf ). The maximum current of a bike is about 6 Ampere when running and the flashers, brake light and front light are on. So, the smaller main fuse will protect the EHC a bit better. However, I have increased some copper paths in the box and have add one more fuse for the ignition / tach, speedometer / tag light and brake light. I attach the actual schema:

Additional I´ll cover the main fuse with self adhesive foam board pcs in order to insulate it a bit thermal from the potting compound and make it more conform to the white papers of the fuses. I don´t know it these changes will cover every issue in the harness but I believe it will improve the life time a bit. I think that BD had the same problems within the years and maybe their internal fuses in the EHC where useless as well due to the potting compound. I just ordered new boards and will test. I hope it will not be a never ending story...

All the best!

Axel

Just an update: I got a return of an EHC where the customer had a short circuit at the horn output cable in the harness. The box had smoked and there was a hole inside. The internal self resettable fuses ( 2 x 9 Ampere parallel in the main line ) had not trip what followed in a burned copper track. I have checked the data sheet of the fuses and have seen that the trip time is far too much. I called to the distributor here and they also told me that the trip time measurements were made in the air and not in potting compound. A potting compound will increase the trip time due to the heatsink function of the potting material. So, I´ll try to change the main fuse to a 7 Ampere device what can also drive the starter solenoid ( 18 Ampere ) for about 20 seconds at 20 degree until it will switch off ( look at page 14, diagram K, RUEF700 of the pdf ). The maximum current of a bike is about 6 Ampere when running and the flashers, brake light and front light are on. So, the smaller main fuse will protect the EHC a bit better. However, I have increased some copper paths in the box and have add one more fuse for the ignition / tach, speedometer / tag light and brake light. I attach the actual schema:

Additional I´ll cover the main fuse with self adhesive foam board pcs in order to insulate it a bit thermal from the potting compound and make it more conform to the white papers of the fuses. I don´t know it these changes will cover every issue in the harness but I believe it will improve the life time a bit. I think that BD had the same problems within the years and maybe their internal fuses in the EHC where useless as well due to the potting compound. I just ordered new boards and will test. I hope it will not be a never ending story...

All the best!

Axel

Attachments

-

325.4 KB Views: 9

I did the same 3000 miles on axels ehc now

I did the same 3000 miles on axels ehc now