Hi,

just an update: I got the message from my distributor that the mixed signal D-Sub will be delivered after April 18. They just have 5 pcs. on stock, what they send tomorrow. Sch... So, I have to wait for 3 weeks more. Does anybody knows if there are other companies with these connectors out? The 50 pin con´s are easy to find but to find a distributor for the mixed signal con´s is a nightmare :-/

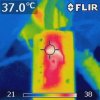

Curtis, an electronic box for custom bikes is not a big challenge from the electrical side. Of course I can not promise anything about long term functions. I just sold almost 1500 electronicboxes within the last 7 years and I learned several lessions with "try and error" within this time what had cost a bit money, time and many coffee and other drinks. I think, I know a little bit about the requirements on the road. There are 4 issues in my opinion: Water, high temperatures, shaking engines and interferences due to spark plugs. I don´t see a problem in the electronic design and the electrical dimensions of the parts on the board. The temperature of the high side switches are pretty low in all situations. I attach an ir photo of the EHC after about 15 minutes engine working with full headlights, following a 20 seconds start procedure, what drives the maximum current in the box. The maximum temperature was almost 40 degree C, what was much lower as I expected. So, the temperature difference to the environment somewhere is around 20 degree C what is good to reduce the risk of tensions on the board and temperature stress to the capacitors and semiconductors.

View attachment 31343

The main challenge in my opinion are the connectors. Even the waterproofed versions of the D-Subs might start to make trouble after some hundred hours of driving, shaking and raining. I believe that the con´s were the main issues in the original EHC. I screw the connectors on the board and have made the biggest possible soldering mask dots on the pcb in order to have as much as possible solder material on the connector contacts after wave soldering. Additional I have ordered the biggest possible copper tracks (70u instead of standard 35u copper) from the pcb factory. So, the contacts itself are (almost) prepared against shaking and bending. However, I think that water around the connectors will limit the lifetime of the EHC. Even the smallest gap in the potting compound after some hundred hours of ride might follow to corrosion on the contacts what results in poor connections and copperoxide bridges. We use a relative flexible potting compund for our devices (Odopal) and we use low quantities of harder in order to increase the dry time of the compound to the maximum time without tensions in our boxes. The results are ok with low returns of my other control boxes within the last years but I can not promise anything about a long lifetime and I only can learn by "try and error" with the EHC. By the way, I have seen that BD had used "semi hard" potting material in the 2007 EHC and later models. It cost them 4 years to learn it...

I got repeatly some price inquires within the last weeks. I felt that it is a bit too early for price offers before the products are ready. However, I got a lot of suggestions and big helps from you in this forum when I had any questions. Thanks a lot for all of the schematics and the comments, what helped me to change the EHC layouts several times until now. So, I would like to offer the first EHC serie to forum members for 290,- USD until these devices are empty (8 x EHC2004 and 9 x EHC 2005 - 2007 carbureted are available). The retail price of the 2004 EHC and 2005 - 2007 EHC for carbureted bikes will be around 480,- USD. I already found a few dealers who will distribute these products in the near future (when the sch... mixed signal connectors are available...).

I´ll be a bit busy with other things within this week and I will be out of the workshop next week due to a local music exhibition. I can fix a few EHC for you when I´m back in my workshop after April 11, if there are any interests. Pls. feel free to use my e-mail adress info(at)elektronikbox.de in case of any questions.

Tim, I hope you vorgive me this advertisement for this time, thanks!

All the best!

Axel

"

I personally don't need one but its goods news for the BD community

I personally don't need one but its goods news for the BD community

I might need one of the 2004 models.

I might need one of the 2004 models.